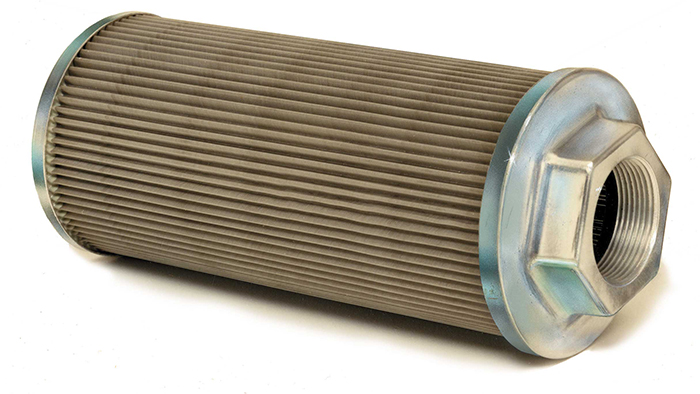

Sump Strainers - All Metal

The traditional all-metal sump strainer has stainless steel pleated elements, in mesh sizes 30 to 200. Continuous epoxy bonded joints will not leak fluid around the element. They may be cleaned and used indefinitely.

Select the desired specifications from the ordering table and build an ordering code number, as shown in this sample:

75 |

- | 2-1/2 |

- | NIPPLE |

- | 100 |

- | RV-3 |

|---|---|---|---|---|---|---|---|---|

GPM |

- | NPT |

- | CONNECTION (spell out NIPPLE if wanted) |

- | MESH |

- | VALVE (omit if not wanted) |

GPM Flow Capacity |

NPT Pipe size |

CONNECTION (Nut or Nipple) |

MESH (Screen size) |

RELIEF VALVE (Optional) |

|

|---|---|---|---|---|---|

|

ALL METAL no symbol |

2 3 3 |

1/4*, 1/2* 3/8*, 1/2* 3/4 |

no symbol (nut) nipple (to get nipple you must specify it) |

30 60 100 200 |

RV-3 (3-psi bypass) RV-5 (5-psi bypass) |

| 5 | 3/4, 1 | ||||

| 10 20 |

3/4, 1 1-1/4 |

||||

| 30 50 |

1-1/2 1-1/2&2 |

||||

| 75 100 |

2-1/2 3 |

NUT STYLE (Metal construction w/cast aluminum top)

GPM RATING |

SCREEN AREA (Sq. Inches) |

NPT (Pipe Size) |

OVERALL DIMENSIONS Diameter | Length |

||

|---|---|---|---|---|---|

| 2 | 25 | 1/4, 1/2 | 1-1/4 |

| |

4 |

| 3 | 35 | 3/8, 1, 1/2, 3/4 | 2-1/8 |

| | 2-11/16 |

| 5 | 50 | 3/4 & 1 | 3-9/32 |

| | 3-1/2 |

| 10 | 110 | 3/4, 1, 1-1/4 | 3-9/32 |

| | 5-3/4 |

| 20 | 145 | 3/4, 1, 1-1/4 | 3-9/32 |

| | 7-3/8 |

| 30 | 260 | 1-1/2 | 4-9/32 |

| | 9-3/4 |

| 50 | 280 | 1-1/2 & 2 | 4-9/32 |

| | 9-3/4 |

| 75 | 350 | 2-1/2 & 3 | 5-7/16 |

| | 12-1/2 |

| 100 | 450 | 2 1/2, 3 | 5-7/16 |

| | 12-1/2 |

| 150 | 675 | 3 | 5-7/16 |

| | 17-3/4 |

NIPPLE STYLE (All-metal construction)

GPM RATING |

SCREEN AREA (Sq. Inches) |

NPT (Pipe Size) |

OVERALL DIMENSIONS Diameter | Length |

||

|---|---|---|---|---|---|

| 2 | 30 | 1/4, 1/2 | 1-1/4 |

| |

4-3/8 |

| 3 | 40 | 3/8, 3/4 | 2-1/16 |

| | 2-7/8 |

| 5 | 62 | 3/4 & 1 | 3-1/16 |

| | 3-11/16 |

| 10 | 125 | 1 | 3-1/16 |

| | 6 |

| 20 | 162 | 1-1/4 | 3-1/16 |

| | 7-9/16 |

| 30 | 310 | 1-1/2 | 4 |

| | 9-3/4 |

| 50 | 340 | 1-1/2 & 2 | 4 |

| | 9-3/4 |

| 75 | 400 | 2-1/2 & 3 | 5-1/16 |

| | 12-5/8 |

| 100 | 500 | 2 1/2, 3 | 5-1/16 |

| | 12-3/4 |

*Relief Valve not available

(Pressure drop through a clean element will not exceed 0.2 psi (0.4-in. Hg) at rated flow of 150 SSU viscosity fluid and 100 mesh.)