Sump Strainers - Nylon Connector

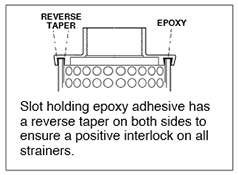

"Nyl-End" sump strainers (Style P) are made with the same selection of stainless steel elements as the standard all-metal units. They differ in that the connector end pieces are molded in a single piece of glass-reinforced nylon resin. Pleated stainless elements are epoxy -bonded in place.

They're as serviceable as all-metal units, but they cost 12 to 50 percent less, depending on size.

All-stainless-steel sump strainers with nylon connectors (Style PASS) are available in the same wide variety of sizes and element mesh sizes as the standard Nyl-End units. For excellent resistance to oxidation and corrosion. (Not always a stocked item).

Select the desired specifications from the ordering table and build an ordering code number, as shown in this sample:

P |

- | 50 |

- | 2 |

- | NIPPLE |

- | 100 |

- | RV-3 |

|---|---|---|---|---|---|---|---|---|---|---|

STYLE |

- | GPM |

- | NPT |

- | CONNECTION (spell out NIPPLE if wanted) |

- | MESH |

- | VALVE (omit if not wanted) |

STYLE |

GPM Flow Capacity |

NPT Pipe size |

CONNECTION (Nut or Nipple) |

MESH (Screen size) |

RELIEF VALVE (Optional) |

|---|---|---|---|---|---|

|

P (std. Nyl. end) PASS (S.S. Nyl-End) |

2 | 1/8, 1/4, 3/8, 1/2 | Nut Only | 30 60 100 200 |

RV-3 (3-psi bypass) RV-5 (5-psi bypass) |

| 3 | 1/4 | ||||

| 3 | 3/8, 1/2, 3/4 | Nut or Nipple (to get nipple you must specify it) |

|||

| 5 | 3/4, 1, 1-1/4 | Nut (no symbol) Nipple Style (see chart below) |

|||

| 10 | 3/4, 1, 1-1/4 | ||||

| 20 | 3/4, 1, 1-1/4 | ||||

| 30 | 1-1/2 & 2 | ||||

| 50 | 1-1/2 & 2 | ||||

| 50 | 2-1/2 | Nipple Only | |||

| 75 | 2-1/2 | Nut or Nipple (to get nipple you must specify it) |

|||

| 100 | 3 | ||||

| 150 | 3 |

NUT STYLE

GPM RATING |

SCREEN AREA (Sq. Inches) |

NPT (Pipe Size) |

OVERALL DIMENSIONS Diameter | Length |

||

|---|---|---|---|---|---|

| 2 | 30 | 1/8, 1/4, 3/8, 1/2 | 1-5/8 |

| |

4-3/16 |

| 3 | 35 | 1/4, 3/8, 1/2, 3/4 | 2-1/4 |

| |

2-11/16 |

| 5 | 50 | 3/4, 1, 1-1/4 | 3-3/16 |

| | 3-1/2 |

| 10 | 110 | 3/4, 1, 1-1/4 | 3-3/16 |

| | 5-3/4 |

| 20 | 145 | 3/4, 1, 1-1/4 | 3-3/16 |

| | 7-3/8 |

| 30 | 260 | 1-1/2, 2 | 4-3/16 |

| | 9-3/4 |

| 50 | 280 | 1-1/2 & 2 | 4-3/16 |

| | 9-3/4 |

| 75 | 350 | 2-1/2 & 3 | 5-3/16 |

| | 12-1/2 |

| 100 | 450 | 2-1/2, 3 | 5-3/16 |

| | 12-1/2 |

| 150 | 675 | 3 | 5-3/16 |

| | 17-3/4 |

NIPPLE STYLE

GPM RATING |

SCREEN AREA (Sq. Inches) |

NPT (Pipe Size) |

OVERALL DIMENSIONS Diameter | Length |

||

|---|---|---|---|---|---|

| 3 | 35 | 3/8, 1/2, 3/4 | 2-1/4 |

| | 3-3/4 |

| 5 | 50 | 1 | 3 |

| | 3-13/16 |

| 10 | 110 | 1 | 3 |

| | 6-1/16 |

| 20 | 145 | 1 | 3 |

| | 7-11/16 |

| 30 | 260 | 1-1/2 | 4-3/16 |

| | 11-3/8 |

| 50 | 280 | 1-1/2 | 4-3/16 |

| | 11-3/8 |

| 50* | 280 | 2-1/2 | 4-3/16 |

| | 9-15/16 |

| 75 | 350 | 2-1/2, 3 | 5-3/16 |

| | 13-3/4 |

| 150 | 675 | 3 | 5-3/16 |

| | 19 |

*No hex between nipple and strainer on this part

(Pressure drop through a clean element will not exceed 0.2 psi (0.4-in. Hg) at rated flow of 150 SSU viscosity fluid.)